.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg)

Technical Characteristics

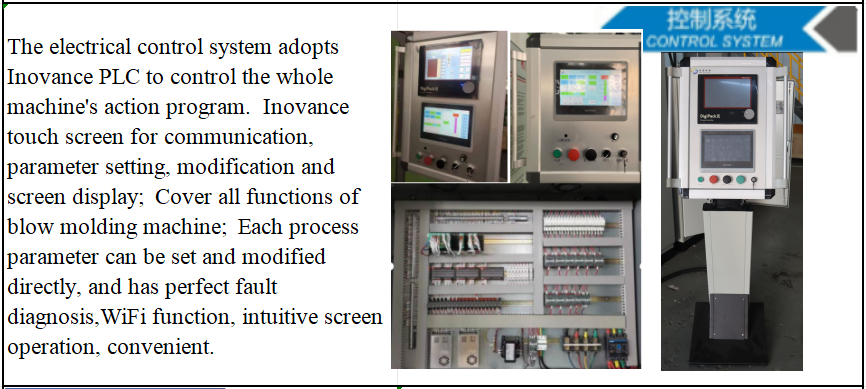

PLC human-machine interface, touch operation. Fault alarm self diagnosis, clear at a glance.

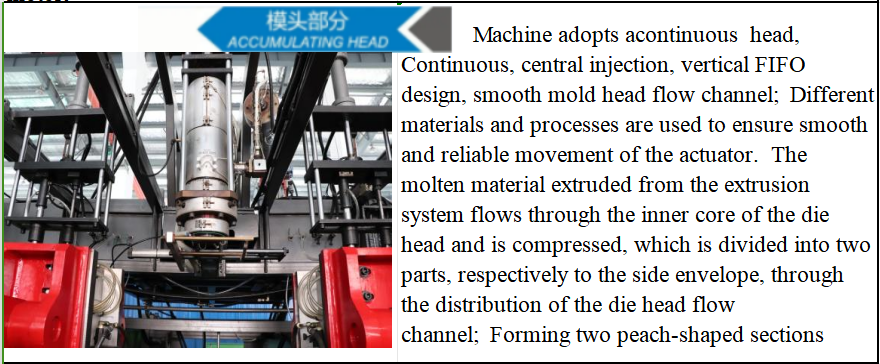

The central feeding type die head completely eliminates the convergence line of the product, and the material change and color change are fast.

The moving mold adopts double linear guide rails and a central locking mold. Uniform force distribution ensures smooth cutting of the product.

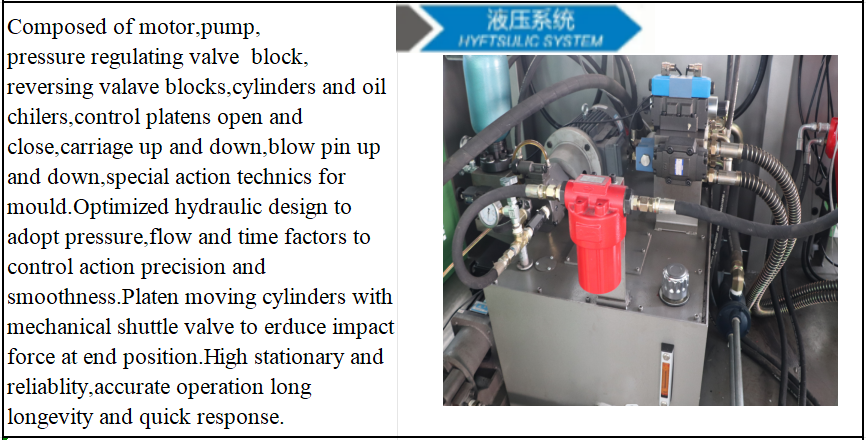

The hydraulic system adopts dual proportion hydraulic control, equipped with imported hydraulic components, with precise and stable action, and energy-saving.

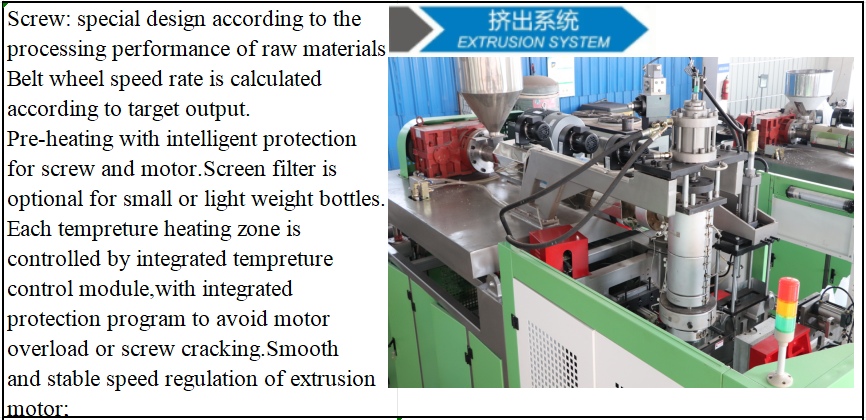

High speed, high efficiency, and low energy consumption plasticizing system ensures even and excellent mixing, ensuring product purity.

Parameters

|

Specifications |

Unit |

Single |

Double |

|

Material |

|

PE、PP、… |

|

|

Max container capacifty |

L |

10 |

|

|

Output (dry Cycle) |

PCS/hr |

1000 |

700x2 |

|

Machine Dimension(LxWxH) |

L x W x H(M) |

3.3x2.1 x 2.6 |

3.4x2.3 x 2.6 |

|

Tatal weight |

TON |

5 |

5.8 |

|

Clamping Unit |

Unit |

Single |

Double |

|

Clamping force |

KN |

90 |

|

|

Platen distance |

mm |

190-550 |

|

|

Mold moving stroke |

mm |

520 |

|

|

Platen size(WxH) |

mm |

360-470 |

|

|

Max mould size(WxH) |

mm |

360-460 |

|

|

Extruder unit |

Unit |

Single |

Double |

|

Screw diameter |

mm |

70 |

80 |

|

Screw |

L/D |

25 |

25 |

|

Extrudedr heating power |

KW |

9.7 |

17.6 |

|

Number of heating zone |

zone |

3 |

4 |

|

Melting capacity |

Kg/hr |

80 |

100 |

|

Die |

Unit |

Single |

Double |

|

Number of hearting zone |

zone |

3 |

|

|

Power of die heating |

KW |

5.7 |

|

|

Max die-pin diameter |

mm |

160 |

|

|

Center distance of double die |

mm |

160-200 |

|

|

Center distance of tri- die |

mm |

110-125 |

|

|

Center distance of tetra- die |

mm |

80-90 |

|

|

Power |

Unit |

Single |

Double |

|

Total power |

KW |

44.9 |

64 |

|

Fan power for screw |

KW |

0.25 |

|

|

Extruding motor |

KW |

22 |

30 |

|

Hydraulic pump motor |

KW |

7.5 |

11 |

|

Air pressure |

MPa |

0.7 |

|

|

Air consumption |

m³/min |

0.6 |

0.9 |

|

Cooling Water Pressure |

MPa |

0.3 |

|

|

Water Consumption |

L/min |

60 |

60 |

|

Average energy consumption |

KW |

25 |

31 |

Machine details:

Features:

Application:

FAQ

.jpg?x-oss-process=image/resize)