KSC-100-30LII

Technical Characteristics

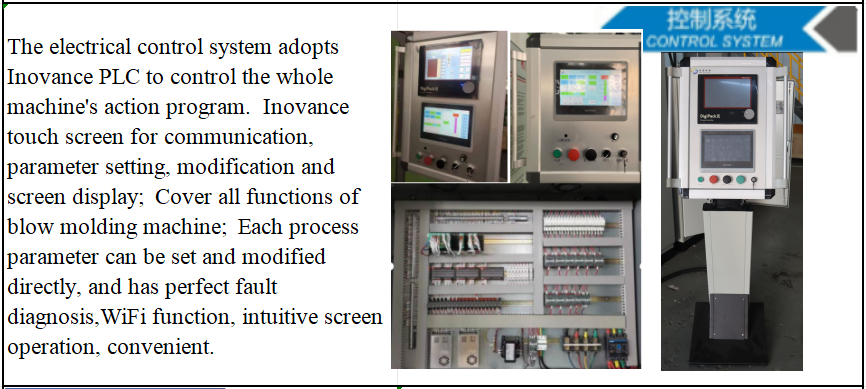

PLC human-machine interface, touch operation. Fault alarm self diagnosis, clear at a glance.

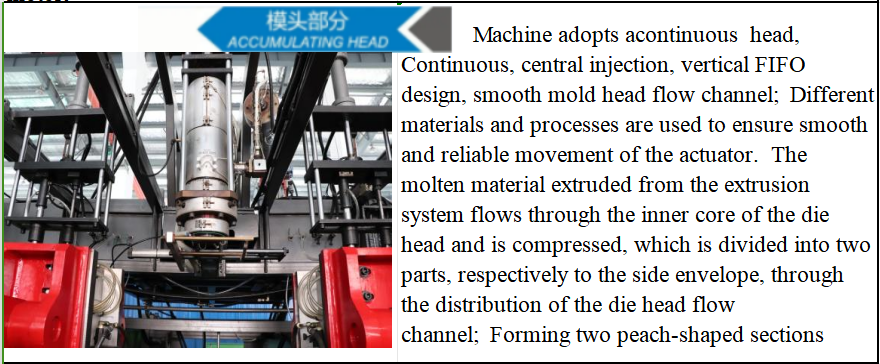

The central feeding type die head completely eliminates the convergence line of the product, and the material change and color change are fast.

The moving mold adopts double linear guide rails and a central locking mold. Uniform force distribution ensures smooth cutting of the product.

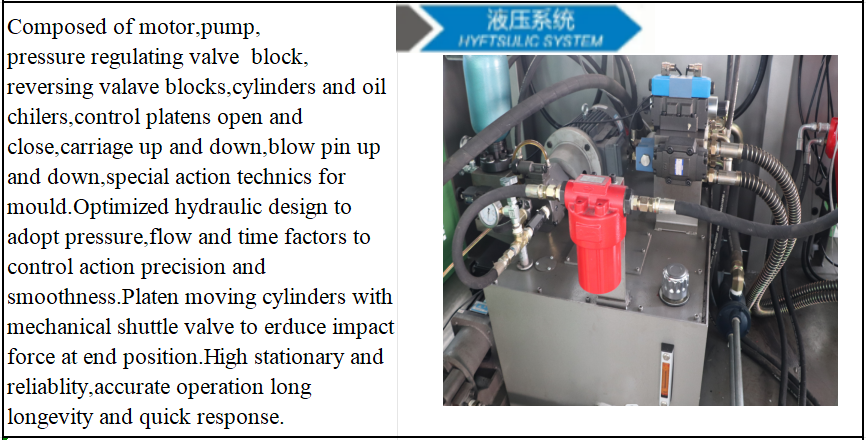

The hydraulic system adopts dual proportion hydraulic control, equipped with imported hydraulic components, with precise and stable action, and energy-saving.

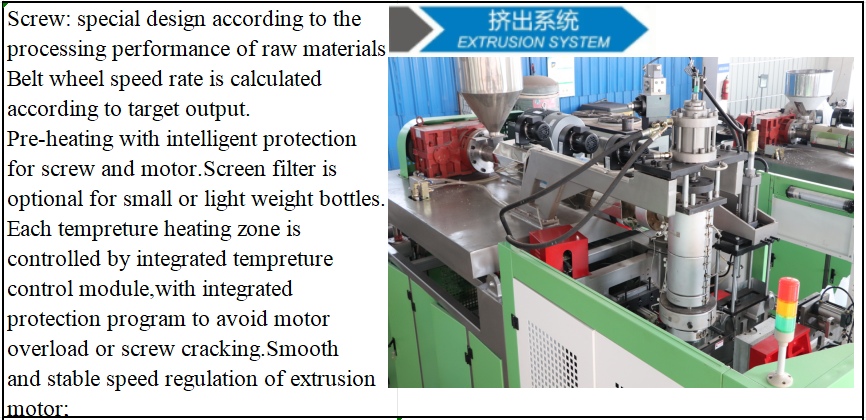

High speed, high efficiency, and low energy consumption plasticizing system ensures even and excellent mixing, ensuring product purity.

Parameters

|

Specifications |

Unit |

Single |

Double |

|

Material |

|

PE、PP、… |

|

|

Max container capacifty |

L |

30 |

|

|

Output (dry Cycle) |

PCS/hr |

600 |

400x2 |

|

Machine Dimension(LxWxH) |

L x W x H(M) |

4.5 x 2.5x 3.0 |

4.9 x 4.0 x 3.2 |

|

Tatal weight |

TON |

12 |

18.3 |

|

Clamping Unit |

Unit |

Single |

Double |

|

Clamping force |

KN |

180 |

|

|

Platen distance |

mm |

460-960 |

|

|

Mold moving stroke |

mm |

750 |

|

|

Platen size(WxH) |

mm |

650x680 |

|

|

Max mould size(WxH) |

mm |

600x650 |

|

|

Extruder unit |

Unit |

Single |

Double |

|

Screw diameter |

mm |

80/90 |

100 |

|

Screw |

L/D |

25 |

24/28 |

|

Extrudedr heating power |

KW |

16/18.7 |

17.5/21 |

|

Number of heating zone |

zone |

4 |

4/5 |

|

Melting capacity |

Kg/hr |

100/140 |

150/220 |

|

Die |

Unit |

Single |

Double |

|

Number of hearting zone |

zone |

3 |

|

|

Power of die heating |

KW |

10 |

|

|

Max die-pin diameter |

mm |

280 |

|

|

Center distance of double die |

mm |

240-260 |

|

|

Center distance of tri- die |

mm |

160/180 |

|

|

Total power |

KW |

74.5/84 |

104/128 |

|

Fan power for screw |

KW |

0.5 |

|

|

Extruding motor |

KW |

30/37 |

55/75 |

|

Hydraulic pump motor |

KW |

18.5 |

22 |

|

Air pressure |

MPa |

0.6 |

|

|

Air consumption |

m³/min |

0.6 |

0.8 |

|

Cooling Water Pressure |

MPa |

0.3 |

|

|

Water Consumption |

L/min |

70 |

100 |

|

Average energy consumption |

KW |

43/47 |

60/71 |

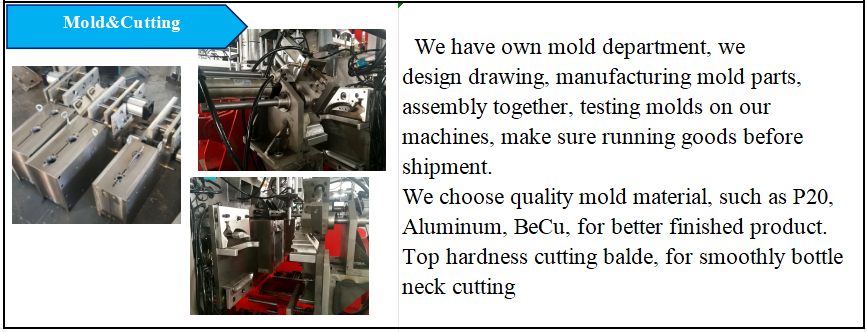

Machine Details with the photos

Features & Advantages

- Reasonable structure design and solid frame manufacturing to insure running stability.

- Thecontinuoustype mold head and the flow channel are made of high-quality nitrided alloy steel, indicating mirror treatment and fast material and color change.

- PLC human-machine interface, touch operation. Fault alarm self diagnosis, clear at a glance.

- The opening and closing mold adopts double linear guide rails, with a central locking mold that is evenly stressed. The product cut is flat, and the joint line is more beautiful.

- The hydraulic system is driven by servo motors and equipped with imported hydraulic components, with precise and stable movements, saving 20% -40% energy compared to conventional models. At the same time, it reduces oil temperature and delays the service life of hydraulic and sealing components.

- The plasticizing system adopts a hard tooth reducer with variable frequency speed regulation, equipped with alloy mixing screws, which are efficient and low-energy, and the plasticizing is uniform.

- Total machine control system well match with scraps on-line deflashing, angle adjustable blowing unit, neck rotary cutting, in-mould labeling, weight testing nd leakage testing, product conveying & packing

Product Application : all kinds of the hollow plastic containers in different industries

- Daily chemical products: shampoo bottles, conditioner bottles, toilet cleaner bottles, facial milk bottles, shower milk bottles, moisturizer bottles, and cleansing bottles

- food and beverage categories: yogurt bottles, lactobacillus beverage bottles, milk bottles, plastic soy sauce bottles, plastic oil kettles

- daily necessities: plastic spray cans, plastic chairs, and plastic tabletop versions

- industrial products: plastic chemical buckets, plastic machine oil buckets, lubricating oil buckets, oil kettles, coolant buckets, stacking buckets

- Transportation facilities: plastic barriers, plastic cones

- Agricultural products: pesticide buckets, pesticide bottles

- Others: float, large toys, toolbox, ocean ball, plastic tray, water storage tank, car fuel tank, medical bed board, etc

FAQ

1. What can you buy from us?

Extrusion Blow Molding Machine,Injection Molding Machine,Injection Blow Molding Machine,PET Blow Molding Machine,Bottle Blowing machine and more.

2. Are Your Price Is the Lowest In This Field? If Not, Why we Buy From You?

The mutual development of you and us is based on products' quality price rate and working efficiency. We don't supply the lowest price machines, but we provide the highest quality price rated machines.

3. Why should you buy from us not from other suppliers?

Experience efficiency and excellence with our comprehensive plastic blow molding machine production services. We are your ultimate partner, providing end-to-end solutions for all your bottle manufacturing requirements.

4. What services can we provide?

Language :English,Chinese,Russia,Spanish

Guarantee of the machine : one year under the normal operation.

Kaisu offer the customer the technology for free for all life time.

5. Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers

products to meet customer' needs.

6. How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also can train the

customer's employees